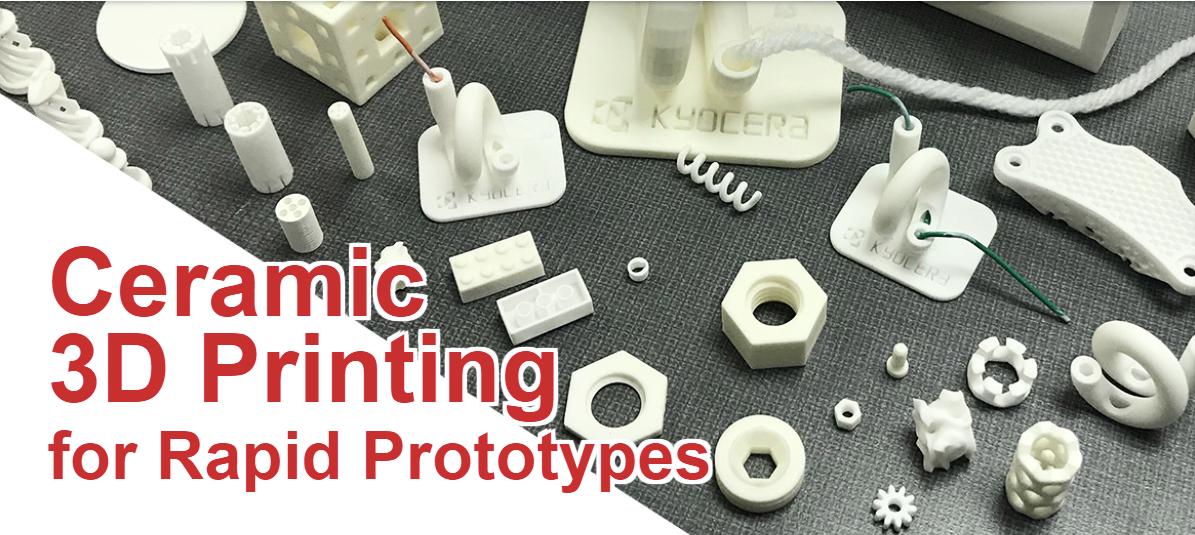

Kyocera Ceramic Additive Manufacturing

KyoCAM

by Kyocera, the Global Leader of Fine Ceramics

Kyocera International, Inc.’s Fine Ceramics Additive Manufacturing

Kyocera International, Inc.’s Fine Ceramics Group has ceramic additive manufacturing capabilities for printing Alumina and Zirconia, two common materials used in advanced ceramics. Products manufactured with this technology yield the same material characteristics as materials produced via more traditional technologies (HIP, CIP, Injection Molding, Press, etc.) yet allow for the creation of complex geometries and customized shapes, making them well-suited for a wide range of applications. In addition, no tooling is required, first samples can be manufactured quickly, and ramps to thousands of units per week can be achieved within 8 weeks.

Alumina is a versatile ceramic material with high strength, stiffness, and wear resistance. Zirconia has high strength, toughness, and resistance to cracking, making it a good choice for applications where durability is important.

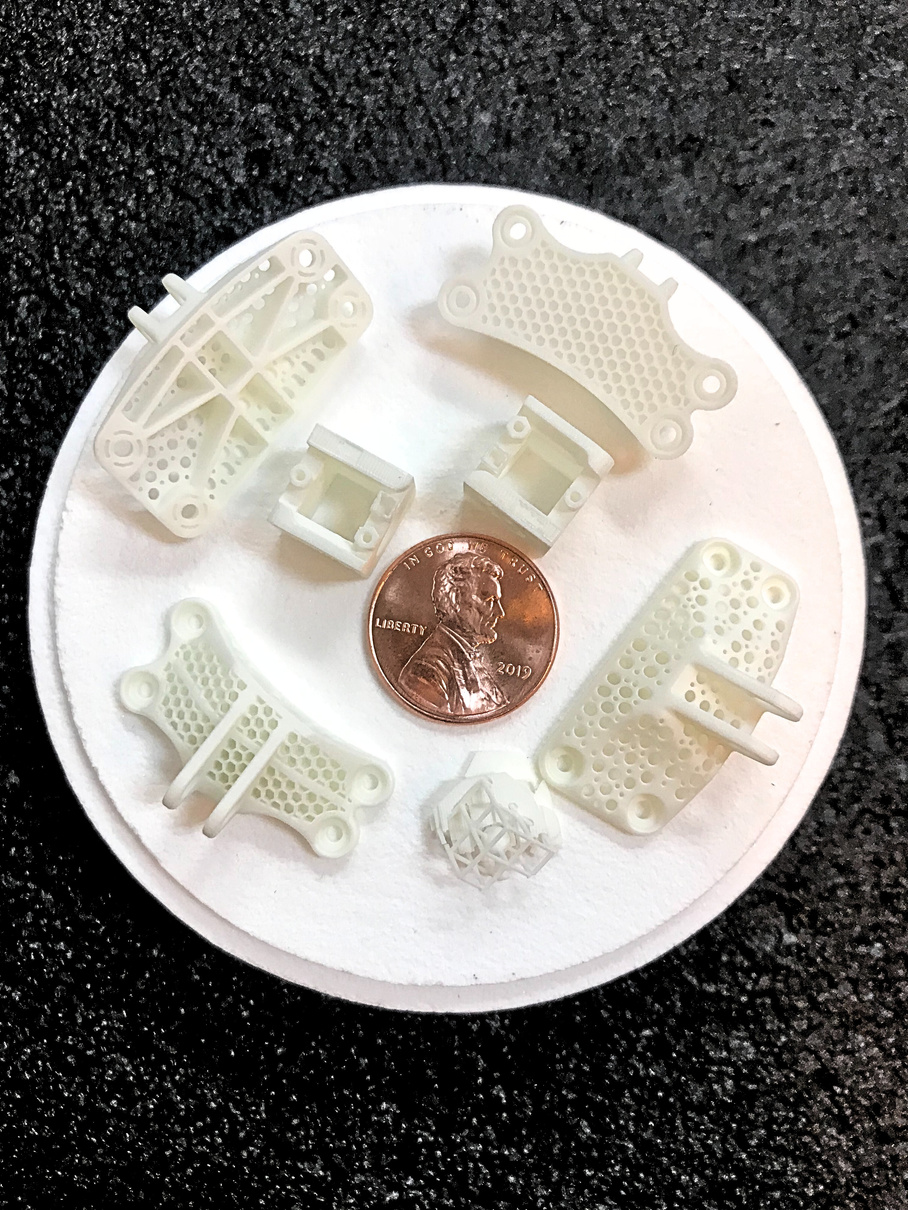

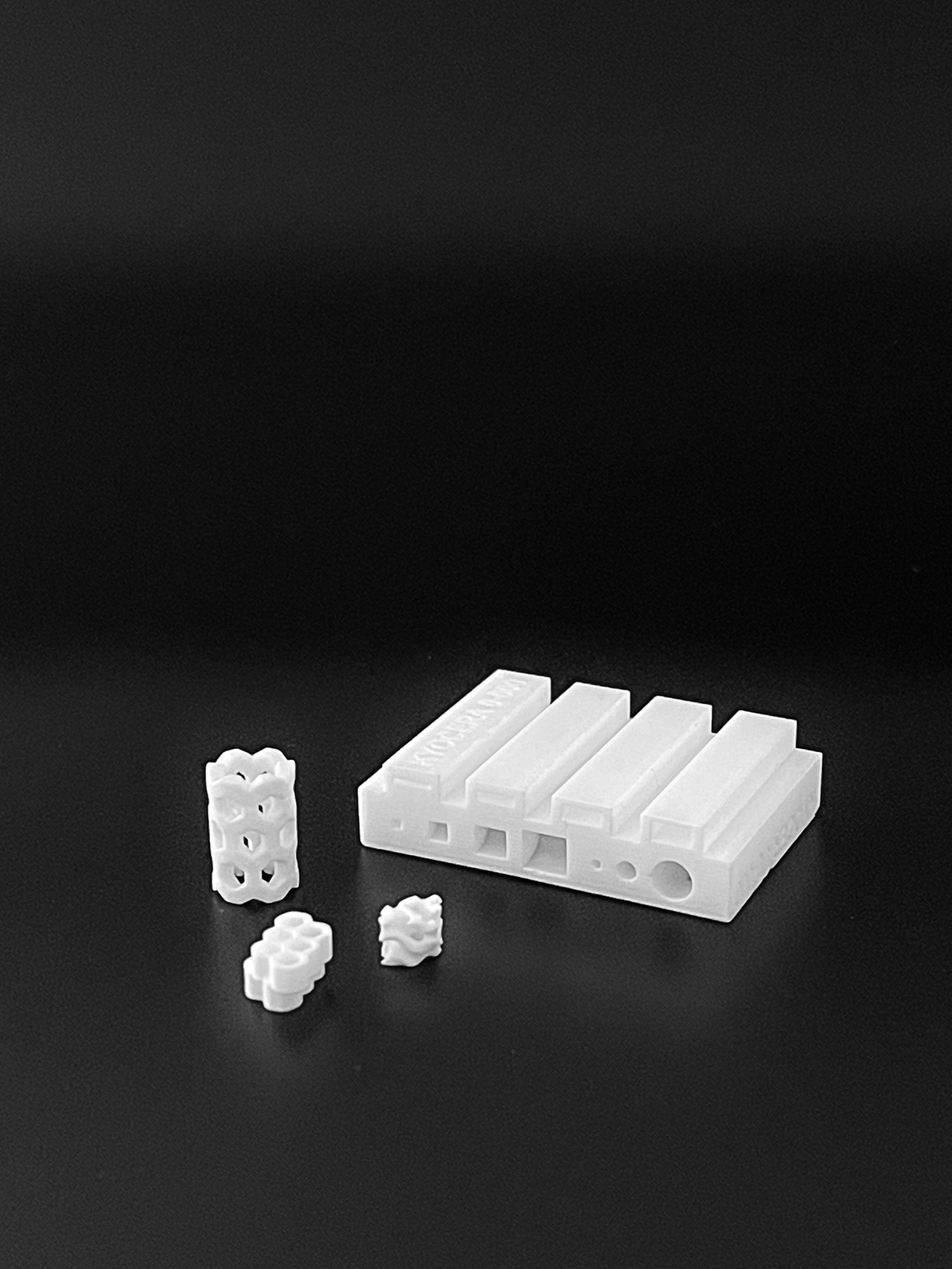

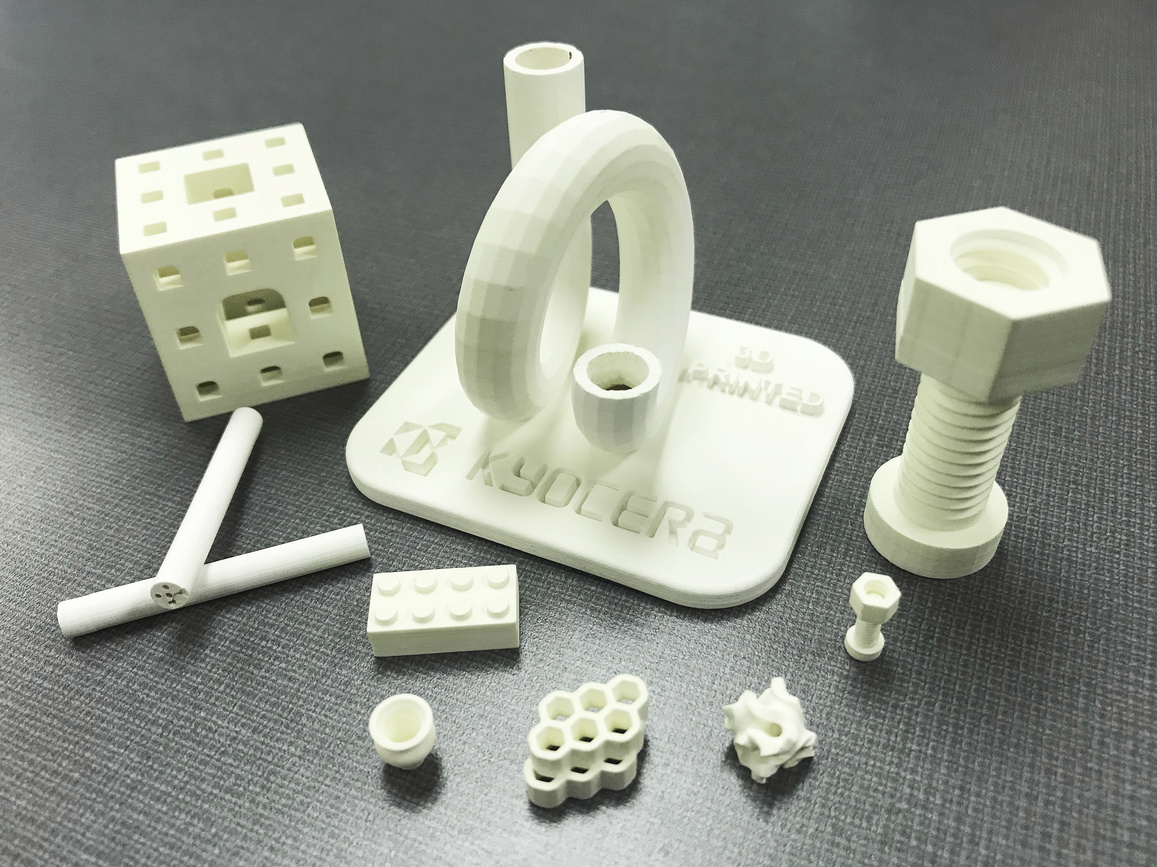

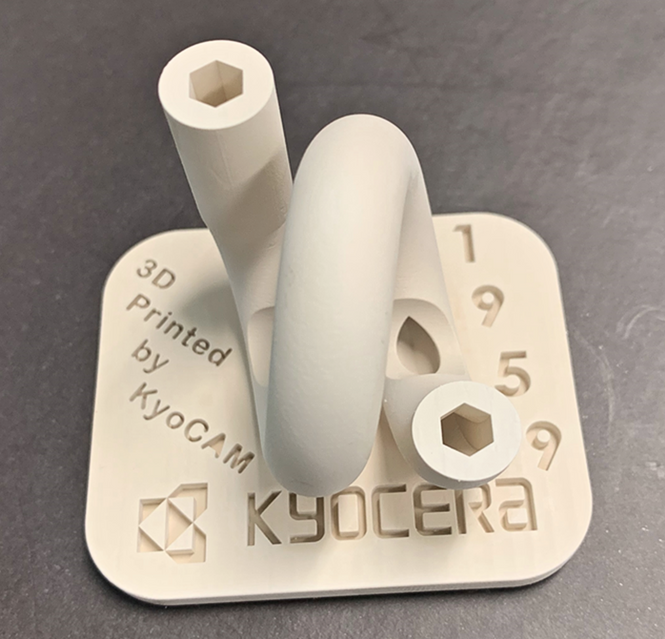

KyoCAM printed ceramic components are excellent solutions for engineers looking for precise pieces, with quick prototyping and mass scale production. With our KyoCAM printing technology you can achieve tight tolerances, small channels, composite shapes, and more. Discover the advanced ceramic additive manufacturing possibilities with KyoCAM below.

Fine Ceramic 3D Printing Applications

Aerospace

Industrial

Medical &

Life Sciences

Energy

Luxury

Consumer

Goods

Manufactured in the USA

KyoCAM Fine Ceramic additive manufactured parts are made in the USA. KyoCAM supports and accepts international 3D printing inquiries.

Benefits of KyoCAM

Complex Shapes Not Possible with

Conventional Forming

Technology

No

Tooling

Required

Short

Lead

Time

Rapid Prototypes:

Shortens Product Development Time

High Purity

> 99.8% Alumina:

- Higher Thermal Conductivity

- Lighter Weight/Lower Density

- Lower Loss Tangent

- Stronger Thermal Shock Resistance

- Heat Exchangers

- Electrical Insulators

Material Technology

Oxide Ceramics

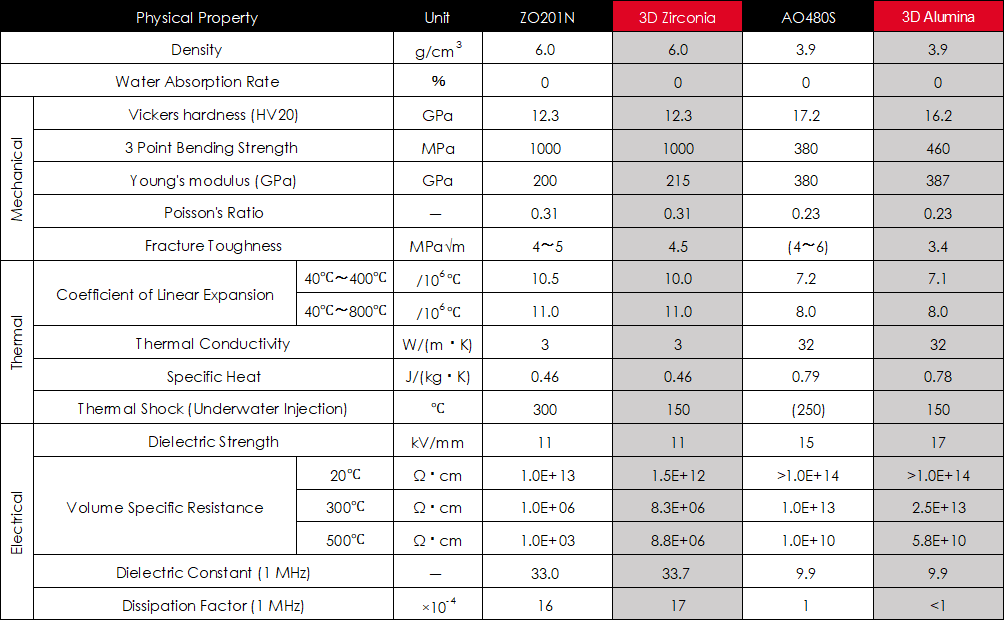

Advanced ceramic materials have characteristics such as:

- Corrosion Resistance

- High Dielectric Strength

- Low Thermal Expansion

- High Hardness

Yttria Stabilized Zirconia (YSZ):

- Higher Wear Resistance

- Higher Tensile Strength/Toughness

- Chemical inertness

- Mirror-Smooth Finish

- Resistance to Heat (Even Molten Metals)

- Dental/Implantable

Alumina and Zirconia Additive Manufacturing Technical Data

Services Available

- 3D Design & Modeling w/CAD

- Structural & Flow Analyses FEA / CFD

- Conjugate Heat Transfer Analysis

- Multi-Axis Computer Aided Machining

If you can imagine it, we can print it!

Designs:

- Complex Surfaces

- Internal Features

- Curved Holes

- Threads

- Textures

Raised or Subtracted Text:

- Serial Numbers

- Graphics

- Logos

- Names

- Personalization

Moving

Assembly:

- Valves

- Hinges

- Bearings

Specifications

Material: Alumina, Zirconia

Maximum Sintered/Finished Size: 400 × 110 × 50 mm

Tolerance: +/- 0.100 mm (as-fired) or +/- 1% of large features >10 mm

Wall Thickness: 0.25 – 10.00 mm

Rapid Prototypes & High-Volume Production

Our 3D printing rapid prototyping allows for an easy transition to high volume production. Request for Quotes (RFQ) must include: 3D CAD file(s) or a 2D Drawing, expected quantity, lead time and target price. A Solidworks 3D CAD file is preferred to expedite the scaling and layout required. Drawing or written specifications will be required to quote for critical dimensions, tolerances, surface finishes, etc. KyoCAM's expected lead time is quick, most parts can be printed, sintered, inspected, and shipped within 2 to 5 weeks.

Please contact us below with any questions regarding our ceramic 3D manufacturing capabilities and RFQs.